When critical lifting tasks arise, Palfinger cranes deliver with their heavy-duty design and exceptional technology. Known across industries, Palfinger cranes are indispensable for a variety of applications, including construction, forestry, waste management, and more.

- From compact models to massive units, Palfinger offers a diverse selection to meet your specific needs.

- Its cranes are built with durability in mind, handling even the most demanding loads.

- In addition, Palfinger's focus to innovation results in user-friendly controls and sophisticated features that enhance operator efficiency and safety.

Choose Palfinger cranes as your reliable partner for heavy lifting solutions, guaranteeing exceptional performance and confidence.

A Comprehensive Guide to Industrial Crane Management

This guideline provides essential instructions on the safe handling and servicing of industrial cranes. It covers a comprehensive range of topics, including crane types, pre-operational assessments, signal systems, load handling procedures, and servicing schedules. Adhering to the guidelines outlined in this document is essential for ensuring safe workflows and minimizing the risk of accidents.

Industrial crane operators must undergo rigorous education to understand the details of their equipment and the operational guidelines. Scheduled upkeep is critical for maintaining the reliability and longevity of industrial cranes. This covers inspections, lubrication, and replacement of worn parts. By following these instructions, operators and engineers can contribute to a safe and productive work environment.

- {Key Safety Features|Critical Safety Mechanisms

- Proper Lifting Techniques

- Procedures for Critical Situations

Choosing the Right Crane for Your Industrial Needs

When choosing the right crane for your industrial applications, several key factors must be carefully considered. The lifting power of the load, the size of the work area, and the surface are all important factors to assess.

, Moreover, considerations such as the type of task being performed, the rate of lifting required, and any present infrastructure must be considered. A well-identified crane will maximize efficiency, safety, and general productivity.

Ul

Li To precisely determine the ideal crane for your unique needs, it is advisably advised to contact a qualified expert. They can offer valuable insights based on your needs and help you make the most suitable crane choice.

Li Thorough planning and choosing of the crane are crucial to provide a safe and productive working atmosphere.

Safe Crane Operation: Essential Tips for Operators

Operating a crane is a responsibility that demands utmost concentration. To ensure safety on the job site, crane operators must adhere to strict procedures. Thoroughly examining the crane and its components before each use is paramount. Operators should also be skilled in operating controls and understanding load capacities. Always communicate effectively with ground crew, maintaining a clear line of communication. By adhering to these best practices, crane operators can reduce risks and contribute a safe working environment.

- Regularly examine the crane for any signs of damage or wear

- Ensure clear communication with ground crew throughout the operation

- Operate the crane within its rated load capacity

- Follow all safety protocols and procedures established by your employer

Remember, safety should always be the top concern when operating a crane.

Palfinger Cranes: The Future of Lifting

Palfinger's commitment to advancement is evident in its state-of-the-art crane technology. From the robust design of the cranes themselves to the intuitive controls, every aspect is meticulously crafted for optimal performance. Their extensive product line caters to click here a diverse range of industries, offering solutions for infrastructure and beyond.

One key area where Palfinger excels is in automation. Their cranes often feature integrated systems that allow for real-time monitoring, data analysis, and remote control. This not only enhances safety but also boosts productivity by streamlining processes and minimizing downtime.

- Additionally, Palfinger is constantly driving the boundaries of crane technology through research and development.

- They are at the forefront of integrating eco-friendly practices into their designs, aiming to reduce their emissions.

- As a result, Palfinger cranes have become synonymous with reliability, flexibility, and industry-leading performance.

The Evolution of Industrial Cranes: From Manual to Automated

Industrial cranes have evolved a remarkable transformation over the years, shifting from manual processes to sophisticated automated devices. Early cranes utilized human effort for lifting and moving heavy objects, often involving complex systems and cumbersome levers. However, the development of new technologies, such as hydraulics and power, gradually transformed crane design.

Today's industrial cranes are a testament to advancement, featuring computerized systems that improve lifting performance.

These modern marvels can perform intricate tasks with remarkable speed and reliability, significantly increasing productivity in various fields. The evolution of industrial cranes illustrates the relentless pursuit of efficiency and automation in modern manufacturing.

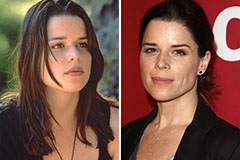

Neve Campbell Then & Now!

Neve Campbell Then & Now! Devin Ratray Then & Now!

Devin Ratray Then & Now! Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Keshia Knight Pulliam Then & Now!

Keshia Knight Pulliam Then & Now!